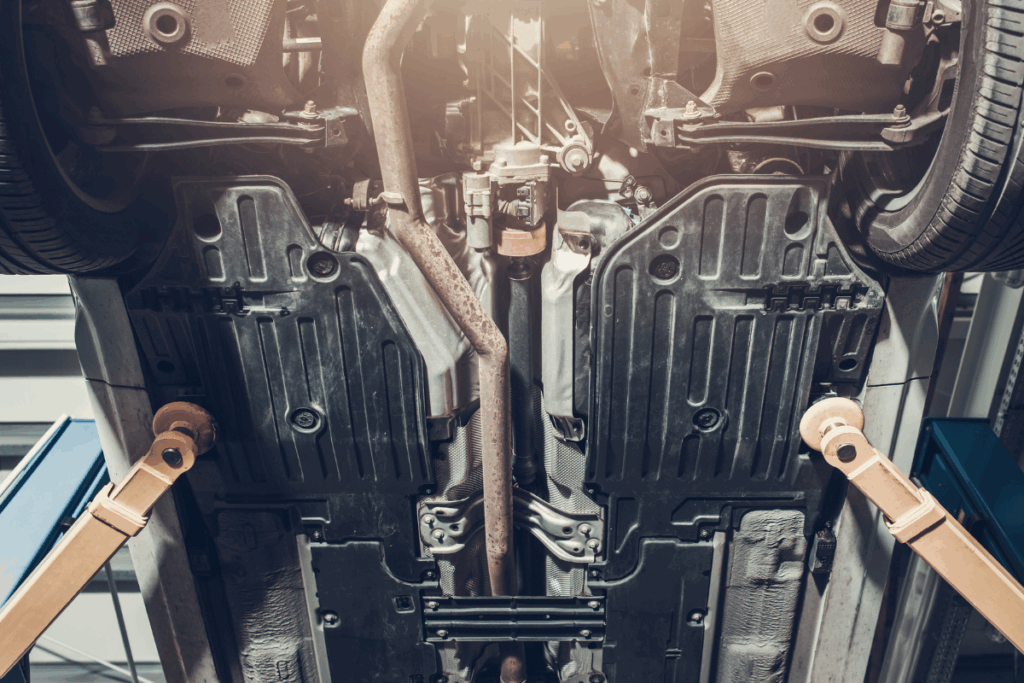

When automobile shoppers comment on a vehicle’s smooth, quiet ride, they often have noise, vibration, and harshness (NVH) damping technology to thank.

NVH dampening is a crucial part of providing drivers with a comfortable, safe, and enjoyable ride. These precision-machined components absorb, redirect, or minimize vibrational energy before it can transmit into the cabin.

When NVH dampers are fabricated and installed correctly, the reward is a vehicle more attractive to buyers. However, even minor flaws in the component’s design can trigger persistent customer complaints, costly warranty claims, or regulatory compliance issues.

Read on as we explore the unique considerations that go into fabricating NVH dampers so our customers can understand how precision machining and process control support acoustic performance, durability, and overall vehicle quality.

Which Materials Work Best For NVH Dampening?

NVH dampers must be built with materials that can absorb shocks and suppress vibration, such as advanced elastomers, composites, or steel-backed inserts. However, the choice of material depends on the damper’s application within the vehicle.

For example, crankshaft dampers must combine a steel hub for torque transmission with a viscoelastic ring capable of dissipating torsional vibrations. Suspension bush dampers, however, require specialized elastomers that offer high fatigue resistance while maintaining damping performance across extreme temperature swings.

Another important factor in material selection is how it responds to fabrication. Heat buildup during cutting or bonding can alter a material’s prime characteristics, affecting its ability to perform reliably over the long term in its final application. This means that fabricators must be careful to select materials that not only have the characteristics to be precision machined to precise tolerances without affecting their elasticity.

At Arrow Automotive, we take a predictive, data-driven approach to material selection by modelling how each candidate material will respond to thermal and mechanical stresses throughout the fabrication process. This methodology helps us identify the best source material that will deliver exceptional results.

Tolerance Stacking For Dynamic Performance

As with many automotive parts and components, NVH dampers rarely work in isolation. They are almost always part of a larger assembly, interacting with shafts, housing, or suspension arms. A deviation of just a few microns can alter the part’s damping characteristics or introduce an imbalance that amplifies, rather than reduces, vibration.

This is where a process called tolerance stacking can help. Tolerance stacking involves summing up the tolerances of multiple parts that are related to each other in a specific assembly to analyze how individual component tolerances accumulate and affect the overall fit, function, or performance of an assembly. It also helps determine the worst-case or statistical variation of a critical dimension or clearance.

This process is especially vital when multiple parts interact within a confined space, such as with engine-mounted dampers.

Our fabricators use advanced machining centers, in-process gauging, and adaptive control systems to maintain consistent tolerances across large production runs. We also validate tolerances in simulation, followed by a physical inspection to ensure that performance won’t degrade in the component’s real-world application.

Furthermore, our touchless scanning systems generate complete 3D models of the fabricated part, allowing us to confirm full compliance with the original design specifications, including tolerances, down to the very last micron.

Surface Finishing To Prevent Secondary Noise Sources

Special attention must be paid to the surface finish of NVH damper components to prevent secondary noises from entering the cabin, such as fretting or squeaking during real-world use. Surface roughness can also generate stress concentrations, shorten service life, and reduce acoustic efficiency.

Kenona engineers employ advanced finishing techniques that ensure the part surfaces meet engineering specifications, enhancing the overall performance of the damper in its application. These processes are automated and monitored in-machine, ensuring repeatability without sacrificing production scheduling.

Removing Contaminants That Can Affect Performance

Like most precision-machined parts, cleanliness is critical to long-term reliability. Residual cutting fluid, particulates, or metal shavings trapped within assemblies can migrate during operation, causing wear, premature failure, or secondary rattling noises. The challenge for fabricators is to ensure no contaminants remain within the blind bores, undercuts, and adhesive bonding channels of the part.

Arrow Automotive integrates advanced automated cleaning cells directly into machining lines, including solvent cleaning systems and high-pressure blow-off stations, followed by particle count validation and cleanliness audits. Our parts cleaning process is especially crucial as automakers integrate more sensors and electronically controlled components into their vehicles.

Read More: Cleanliness Requirements Of Precision Machined Parts

Comprehensive Testing To Ensure Reliable Performance

NVH dampers require unique testing methodologies that replicate real-world vibration frequencies, amplitudes, and thermal conditions.

For example, a dynamic mechanical analysis measures the part’s damping properties across a range of frequencies and temperatures. NVH parts also require resonance testing to identify a component’s natural resonance frequencies. Additional tests are conducted to ensure that damping performance does not degrade under repeated load and environmental stresses.

Kenona engineers embed these validation steps into the production workflow to catch any subtle defects before the part is moved further into the production process.

Read More: Why Metrology Matters In Precision Machining

Access Top-Quality Precision Machine Solutions With The Team At Arrow Automotive

The engineering experts at Kenona Industries, a division of Arrow Automotive, use advanced technology to ensure that every automotive part and component we deliver, including NVH dampers, perform effectively through thousands of operating cycles in their real-world applications.

As a leading automotive components supplier, we’ll work closely with your R&D team to ensure you get the best results for your precision machine projects every time. Get in touch with us when you’re ready to build!

Contact Kenona Industries For A Quote On Your Next Design And Fabrication Project

Kenona Industries is a world-class supplier of automotive components to leading OEMs and Tier 1, 2, and 3 manufacturers. Discover what sets us apart by requesting a quote for your next project today!