Looking back at the early pioneers of metal parts machining and fabrication, we can’t help but wonder how they’d react if they could see the tech-driven processes we use in metalworking today. We think they’d be impressed – and a little envious!

Precision machining is an example of a manufacturing technique that has revolutionized how we build things. This process pairs designers and engineers with the most advanced software and automation technologies to create complex parts and components that would have been extremely difficult to build with traditional fabrication techniques. Precision machining is now becoming the accepted norm for many industries where quality and accuracy are critical, such as aerospace, medical devices, and automotive.

How Precision Machining Works

At the root of precision machining is automated computer numerical control technology (CNC), which translates 3D drawings created by computer-aided manufacturing (CAM) software into code for the CNC machining equipment to read. This code includes detailed instructions on how the mills, lathes, drills, grinders, and other precision machine tools should shape the workpiece to create the desired part.

The instructions from the CNC software are so precise that virtually any part that requires tight tolerances or deep geometric cuts can easily be fabricated. Additionally, since the tools use the same instructions for the whole production run, CNC technology ensures the same level of accuracy, quality, and repeatability for every part that comes off the line.

Many standard CNC tools work on the X, Y, and Z linear axes of the part at the same time. However, high-precision CNC machining often has multi-axis capabilities, which add A/C and B axes for additional efficiency and greater fabrication precision. Multi-axis machines can have as many as nine axes, which allows them to create parts with ultimate precision as the tools can access the workpiece from virtually any direction.

Other features of CNC technology include reduced waste, minimal defects, faster set-up time, and automated tool changers, all adding up to optimized cost-effectiveness for manufacturers.

Read More: What You Need To Know About Precision Machining Techniques

Precision Machining’s Role In Auto Components Manufacturing

The auto sector has transformed significantly since Henry Ford first rolled out mass production of the Tin Lizzie in 1908. Changes in consumer needs in aerodynamics, weight reduction, vehicle performance, fuel efficiency, comfort, and safety have demanded significant changes in design and manufacturing, starting with the smallest of components. Most significantly, auto manufacturers are adding EVs to their inventory, introducing fresh design requirements to parts and components suppliers.

Our Kenona facility has adapted to these changes by continually innovating to meet the needs of modern automobile designers. These innovations include adopting machining techniques supported by CNC technology to solve design, modeling, and geometric dimensioning and tolerancing (GD&T) challenges for aluminum, gray, ductile, and HiSiMo iron components for automotive applications.

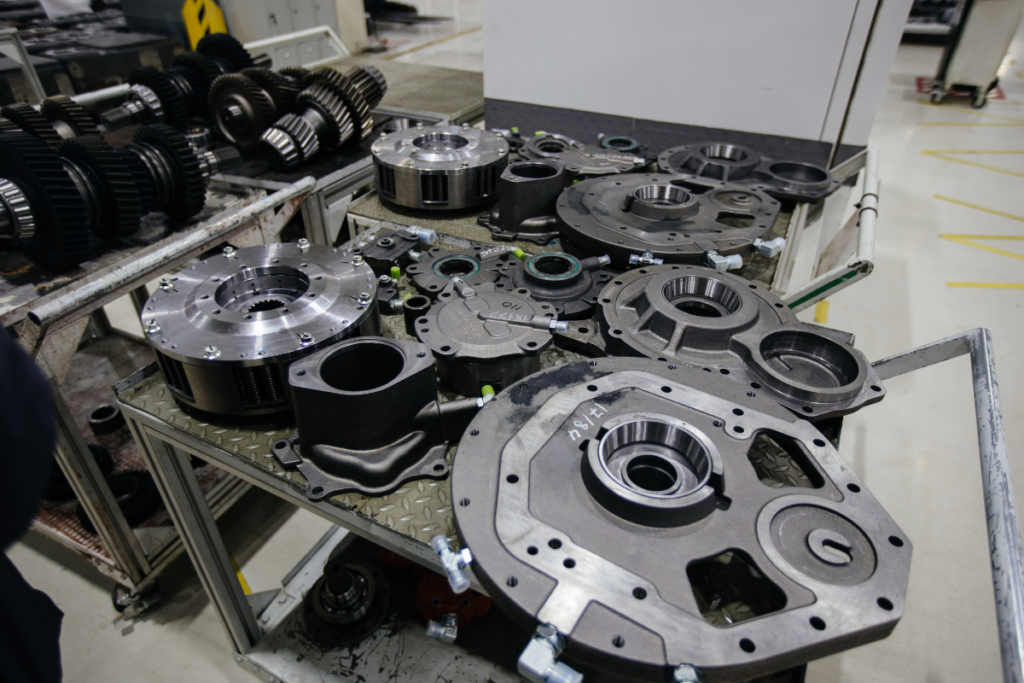

Here are some of the products we create using precision machine technology:

- Steering and suspension components, including control arms, tie rods, ball joints, steering knuckles, and wheel hubs

- Hydraulic valve housing and subassemblies

- Exhaust and turbocharger manifolds, headers, catalytic converters, and mufflers

- NVH dampers

- Axle subassemblies

- Chassis components, including tow hook subassemblies, brackets, mounting points, structural supports, and body panels

- Brake components, including calipers, rotors, brackets and master cylinders

- EFI fuel rail subassemblies

- Engine components such as heads, engine blocks, crankshafts, camshafts, pistons, valves and connecting rods

- Transmission mounting bracket subassemblies, gears, gearboxes, shafts, and clutch components

- BEV battery enclosure component subassemblies

- BEV rockers and other structural assemblies

- Trim components such as dashboard components, door handles, trim panels, grilles, emblems, and decorative accents

Thanks to precision matching based on CAD and CNC technology, we can deliver these and other parts faster, more efficiently, and more cost-effectively than with traditional metalworking methods.

Read More: Our Capabilities

Kenona Industries: Putting Modern Technology To Work For Your Precision Machining Projects

Since 1988, Kenona Industries a division of Arrow Automotive has followed a tradition of integrating the latest technology in our machining cells with speed and agility, enabling us to fabricate high-volume, precision-made components for gas-powered and electric vehicle components. We’re now a world-class, high-quality provider of these components to leading automotive OEMs and Tier 1, 2, and 3 suppliers.

Our team of machinists, automation experts, automation engineers, controls engineers, software engineers, and robotics experts have the skills, experience, and knowledge to fabricate complex, cost-effective metal design and fabrication solutions that consistently deliver high quality, durability, and performance.

When you need quality precision machined parts and components, call Kenona Industries first.

Contact Kenona Industries For A Quote On Your Next Design And Fabrication Project

Kenona Industries is a world-class supplier of high-volume, precision-made components to leading automotive suppliers. Discover everything that sets us apart by requesting a quote for your next project today!