As a leading precision-machine parts and components supplier to government agencies and defense contractors, Kenona Industries, a division of Arrow Automotive, prioritizes not just providing high-quality castings and extrusions but also ensuring compliance with International Traffic in Arms Regulations (ITAR) guidelines for data control, documentation, and accountability.

In this month’s blog, we discuss ITAR’s impact on casting and extrusion fabrication for defense applications.

Why Is ITAR Compliance Critical For Defense Product Fabrication?

ITAR sets rules governing the manufacture, handling, and export of defense-related materials and data listed on the United States Munitions List (USML). Products on the USML include firearms, missile systems, military aircraft, tanks, and related technical data and equipment. These rules ensure that sensitive technologies and information are protected against unauthorized access or transfer.

At Kenona, ITAR compliance affects every operational layer. We understand that even the smallest component detail can contain proprietary geometry or performance characteristics linked to classified systems, so we’ve implemented stringent access controls and established documented auditing, protection, and traceability processes for every drawing, toolpath, and supplier relationship.

Our ITAR certification also allows us to combine the best of our capabilities to support defense-related products. For example, our engineers’ ability to meet the high-precision standards required by top-tier automotive OEMs, such as tight tolerances, repeatability, and efficiency, is complemented by additional safeguards mandated by ITAR guidelines that extend well beyond standard ISO or IATF quality frameworks.

For example, while IATF 16949 certification for automotive component manufacturers emphasizes defect prevention and continuous improvement, it does not require the documentation control, data encryption, and export restrictions that exist under ITAR. Our ITAR certification uniquely positions our production facility as a hybrid manufacturing environment that merges high-volume automotive precision with military-grade security and traceability.

Which Processes Are Impacted By ITAR Guidelines?

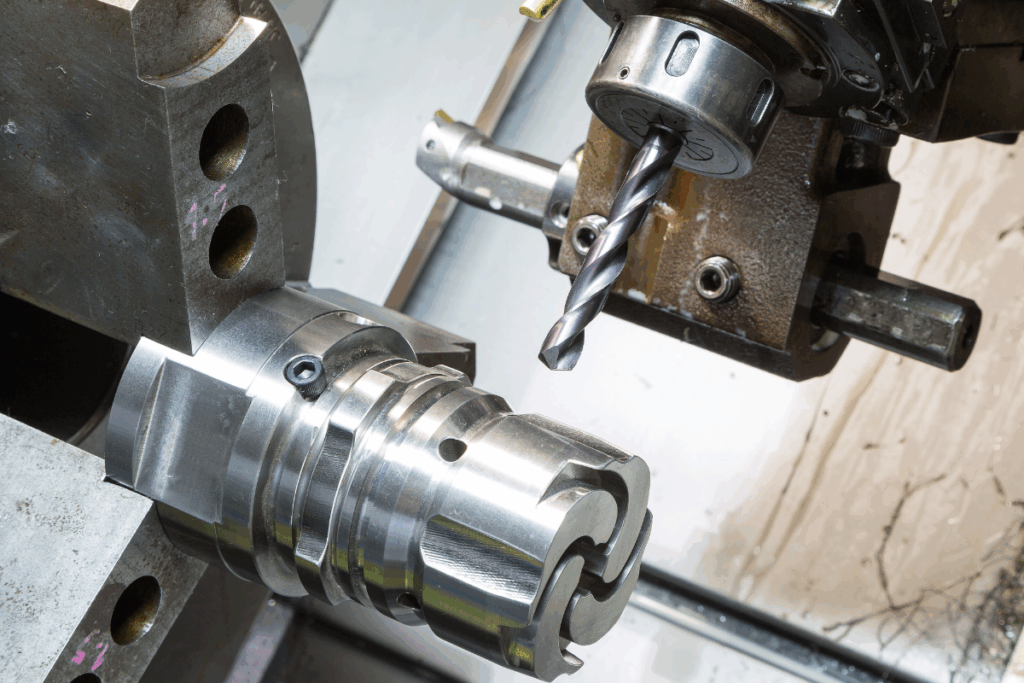

From a process standpoint, ITAR-compliant precision machining adds complexity in these three distinct areas:

- Material Procurement

Every billet, casting, and extrusion must come from approved, documented sources. Material certificates, lot numbers, and chemical compositions must align precisely with contract specifications and remain traceable throughout the precision-machining process.

- Process Documentation

Defense contracts typically require formal process flow documentation, first-article inspections (FAI), and adherence to standards such as AS9102 or MIL-STD-1916. As an ITAR-compliant production facility, we’ve integrated these processes seamlessly into our quality systems.

- Precision Verification

Defense projects require mechanical and metallurgical consistency in every part and component. Surface integrity, grain structure, and coating adhesion can directly influence product performance in the final application, enhancing their ability to withstand extreme environments, such as heat, pressure, vibration, and corrosive exposure.

Our investments in meeting ITAR requirements in these areas ensure that our defense products are manufactured to the highest quality standards under secure conditions that protect related sensitive information.

ITAR-Compliant Castings Vs. Extrusions For Defense Applications

Precision-machined castings and extrusions serve critical roles in the production of military-grade components. However, there are significant differences in their properties, manufacturing constraints, and end-use suitability.

For example, castings are ideal for intricate parts, including structural housings, transmission cases, suspension arms, and turret components. These components must endure heavy loads, harsh environmental conditions, and repeated impact with efficiency. Aluminum, magnesium, titanium, and other specialty alloys are commonly used in casting. Every step of production, including design, melting, pouring, and cooling, must be carried out in ITAR-registered production facilities.

On the other hand, extrusions are commonly used for vehicle frame components and electronic housings that require fatigue resistance and structural reliability. The process involves forcing metal, such as aluminum or titanium, through a die to create a continuous profile with consistent cross-sections. These profiles are then cut, precision-machined, and finished to specification.

Read More: What Our IATF And ITAR Certifications Mean To Our Customers

Partner With Kenona Industries For High-Quality, ITAR-Compliant Precision Machine Parts And Components For Defense Applications

Defense contractors and government agencies understand the critical need to partner with precision-machined parts and equipment suppliers that are experienced in both casting and extrusion fabrication under ITAR. That’s why Kenona Industries is a leading supplier of high-quality products for military applications in the United States.

Our skilled and experienced engineers couple their diverse engineering capabilities with the robust cybersecurity, export control documentation, and supply chain integrity required under ITAR guidelines. When you partner with Kenona, you’re assured of defense parts and equipment that will exceed your expectations, along with all the protocols necessary to ensure your project data, information, and details are compliant and protected at all times.

When you’re ready to start building, call our team first!

Read More: Our Capabilities

Contact Kenona Industries For A Quote On Your Next Design And Fabrication Project

Kenona Industries is a world-class supplier of automotive components to leading OEMs and Tier 1, 2, and 3 manufacturers. Discover what sets us apart by requesting a quote for your next project today